How to Address Signal Attenuation and Electromagnetic Interference in Subsea Cables?

The underwater cable, which transmits all power and data signals, serves as the critical physical link between ROVs, submersibles and the surface control station. Deploying this vital connection—often termed a "subsea signal highway"—presents significant engineering challenges due to an extremely harsh operating environment, centered on two fundamental issues:

1. Severe Signal Attenuation and Loss: For underwater cables, although signal transmission within the cable is not directly absorbed by the water, long-distance transmission—especially of high-frequency signals—experiences a significant increase in conductor resistance due to the "skin effect", combined with dielectric loss. Together, these factors result in high equivalent attenuation and low available bandwidth.

2. Complex Electromagnetic Interference: This is the primary threat to wired communication, originating from the equipment's power systems and the complex underwater environment. It demands that the cable possess excellent internal shielding and crosstalk resistance, which is precisely the core problem addressed by twisted-pair and array configuration processes.

Therefore, constructing a high-speed, stable, and ultra-long-distance communication channel is beyond the capability of conventional cables. This necessitates that subsea cables must, from the very beginning of their design, incorporate advanced internal processes specifically aimed at combating loss, increasing capacity, and resisting interference. Different communication requirements are precisely the starting point for selecting different combinations of these processes.

I. Overview of Foundational Processes

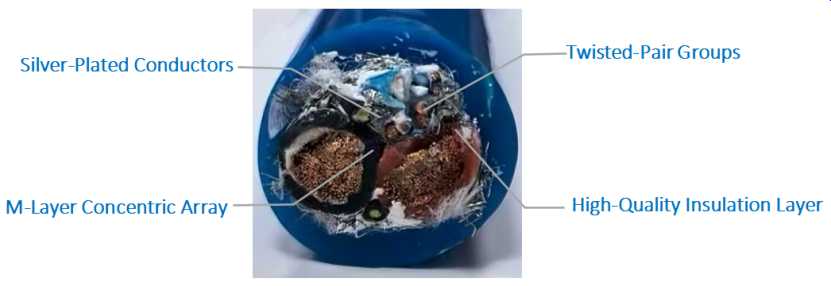

Silver-Plated Conductors: This process paves a "superconducting highway" for high-frequency signals to counteract the negative impacts of the skin effect. By establishing a low-resistance pathway on the conductor surface, it significantly reduces high-frequency attenuation, forming the material science foundation for enhancing transmission distance and bandwidth.

Twisted-Pair Groups: A precision technique that converts interference into cancelable "common-mode noise." Because this noise is identical on both wires, it is automatically nullified when the difference is calculated, allowing the information-carrying differential signal to be clearly extracted. This enables pure signal transmission in complex electromagnetic environments.

High-Quality Insulation Layer: Its primary function is electrical insulation to prevent short circuits. Beyond this, it secures the geometric position of the conductors and provides an environment with highly stable dielectric properties, ensuring predictable and non-drifting signal transmission characteristics.

M-Layer Concentric Array: Through a layered and regularized coaxial layout, this design positions cable units with different functions optimally. It ensures exceptionally high consistency in parameters such as capacitance, inductance, and propagation speed among these cables, thereby achieving perfect signal synchronization.

II. How to Match Processes to Your Requirements?

Combination 1: Conquering Electromagnetic Interference–Creating a "Silent" Data Channel

Target Scenario: The cable needs to integrate multiple signal types (e.g., analog sensors, digital control, high-frequency video) and high-power supply; or the external environment has complex electromagnetic noise (e.g., near propulsion motors, sonar).

Recommended Process Combination: Twisted-Pair Groups + M-Layer Concentric Array

How It Works:

Twisted-Pair Groups act as the "tactical unit," using differential signal transmission to locally cancel common-mode interference coupled onto the pair.

The M-Layer Concentric Array serves as the "strategic layout," categorizing and isolating different elements like twisted-pair signal lines and power lines. Sensitive signal pairs can be placed in a protected inner zone, while high-interference sources (e.g., power lines) are placed in an outer zone or a separate sector, with grounding layers in between to fundamentally block crosstalk paths.

Client Benefit: Achieves zero-interference co-transmission of multiple services. Ensures HD camera feeds are free of striping, sensor data is free of jumps, and control commands are absolutely reliable, even when running parallel to hundreds of volt power lines for kilometers.

Combination 2: Pursuing Extreme Speed and Fidelity–Creating a "Lossless" High-Speed Channel

Target Scenario: Requires long-distance transmission of high-frequency signals (e.g., HD/UHD video, raw sonar data, high-speed network traffic); has extreme requirements for low signal attenuation, delay, and waveform distortion.

Recommended Process Combination: Silver-Plated Conductors + M-Layer Concentric Array

How It Works:

Silver-Plated Conductors directly target the "skin effect," reducing the surface resistance to high-frequency current—a material science breakthrough for minimizing internal conductor loss.

The M-Layer Concentric Array ensures highly consistent characteristic impedance along the entire cable length through ultimate geometric symmetry and dielectric uniformity. This impedance matching provides a system-level guarantee against signal reflection, preserving waveform integrity.

Client Benefit: Gains longer effective transmission distance, higher available bandwidth, and lower bit error rates. Suitable for remote HD monitoring, big data retrieval, and precision synchronous control scenarios.

Combination 3: Ensuring Absolute Reliability and Consistency–Creating an "Industrial-Grade" Precision Channel

Target Scenario: A multi-core cable requires dozens or even hundreds of signal pairs to have perfectly identical performance (e.g., phased-array sonar units, multi-channel acquisition systems); or the cable must maintain consistent performance under severe bending and vibration.

Recommended Process Combination: M-Layer Concentric Array + High-Quality Insulation Layer

How It Works:

The symmetry of the M-Layer Concentric Array guarantees that all pairs in symmetric positions within the same layer share physically identical electromagnetic environments, leading to inherently consistent electrical performance (delay, attenuation).

The High-Quality Insulation Layer, combined with the array, solidifies this precise structure, preventing deformation during dynamic use and ensuring long-term, stable performance.

Client Benefit: Achieves near-perfect synchronization and consistency across channels, along with repeatable and predictable performance throughout the product lifecycle—forming the cornerstone for high-end scientific research and industrial applications.

III. Customized Decision Guide for Clients

Your Primary Concern | Core Challenge | Recommended Priority Process Combination | Expected Outcome |

Anti-Interference, Multi-Signal Isolation | Internal Crosstalk, External Electromagnetic Noise | Twisted-Pair Groups + M-Layer Concentric Array | Achieves pure signal transmission in complex electromagnetic environments. |

High Frequency, Long Distance, Low Loss | Signal Attenuation, Bandwidth Limitation, Waveform Distortion | Silver-Plated Conductors + M-Layer Concentric Array | Maximizes bandwidth and transmission distance, ensuring signal integrity. |

Multi-Channel Consistency, Dynamic Stability | Inter-Channel Variation, Performance Shift Due to Bending | M-Layer Concentric Array + High-Quality Insulation | Ensures uniform, stable performance, suitable for precision system integration. |

Extreme Comprehensive Performance | All the above challenges coexist.

| Full Process Adoption (Silver-Plating + Twisted-Pair + High-Quality Insulation + Concentric Array) | Creates a premium subsea interconnect solution for the most demanding missions. |

In summary, a reliable subsea cable is the product of the combined action of multiple internal core processes. Each process targets specific challenges, and their effective combination and integration are key to achieving the defined communication and mechanical specifications.

To obtain the optimal solution, we recommend initiating preliminary cable design early in your project. You can provide a schematic or technical sketch containing the following core elements:

²Cable core structure layout (e.g., quantity and planned placement of signal pairs, power lines, optical fibers, etc.)

²Expected electrical performance indicators (e.g., characteristic impedance, operating frequency, attenuation requirements)

²Key mechanical and environmental parameters (e.g., minimum bending radius, tensile strength, operating depth and pressure)

Based on your design input, our engineering team can conduct a rapid technical feasibility assessment and engage in efficient, precise collaborative work with you regarding material selection, process details, and performance optimization. This ensures the final product fully meets your system integration requirements.

For a detailed design guide or preliminary technical discussion, please feel free to contact us via email at:inquiry@rouline.com

Copyright and Sharing Notice

© 2024 RouLine. The article "Lossless Signal Transmission for Underwater Equipment: Core Cable Processes Decoded for Subsea Cables" is an original technical publication of our company. No individual or organization may reproduce or use this article for commercial purposes without prior authorization.

We welcome sharing on non-commercial platforms for the purpose of learning and exchange, provided that the original author and source link are clearly credited.

Article Information

Author: RouLine

Source: Knowledge

Original Link: https://www.rouline.com/kn3-subsea-cable-n.html

Publication Date: 31st Dec., 2025

To Learn More

If you have requirements for custom underwater equipment cables or wish to obtain more technical documentation, please contact us via our official website at www.rouline.com or by email at inquiry@rouline.com.

Post time:2026-01-02