Subsea Towing Cable

Subsea Towing Cable

Integrated System Solution

Power Transmission

Signal Transmission

Tensile Strength

Corrosion Resistance

Key Performance Parameters

Tensile Strength: from 0 to 8 tonnes

Core Process: Silver-Plated Conductors, Twisted-Pair Groups, High-Quality Insulation Layer, M-Layer Concentric Array. Click for more core process details.

Extensive range: 1 to 60 cores

Conductor Cross-Sections: 0.08 mm² to 35 mm²

Other Options: Water Tightness Compound/Sealant/Water-Blocking Yarn

Corrosion Resistance:resistance to hydrolysis, corrosion, abrasion, and ultraviolet light.

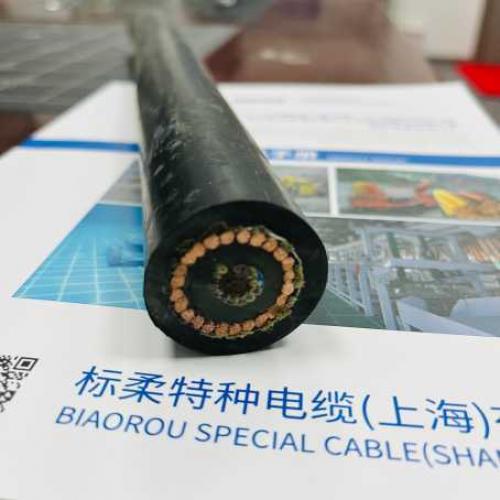

Construction

Conductor:Fine-stranded, extra-flexible tinned soft copper wire.

Insulation: TPE, TPE, TPV, XLPE, DPEM

Core Structure: anti-twist layering, grouped gap filling, twisted pairs, and layered binding

Optical Fiber:Single-Mode/Multi-Mode

Shielding: A combination of tinned copper braid provides 360° EMI/RFI shielding

Tensile Strength Member:Central Kevlar Core, Interstitial Kevlar Fill, High-Tensile Steel Wire

Outer Sheath: XLPE

Electronic Data

Custom Tensile: Strength: 0 - 8 tonnes

Working Voltage: 300V ~ 1 kV (for higher voltage, please contact )

Test Voltage: 2000 V

Insulation Resistance: ≥20 MΩ·km (at 20°C)

Minimum Bending Radius: Dynamic: 7.5 × OD, Fixed: 4 × OD

Operating Temperature: -40°C to +105°C

Ordering Information

MOQ: 100 meters (or project-based negotiation)

Standard Lead Time: 6-8 weeks after order confirmation

Customization: Fully supported

Samples: Free Samples, Only shipping charges apply.

Engineered for Diverse Subsea Applications

Unmanned Underwater Vehicle(UUV)

Towed Sonar Operations

Submarine Sonar Support / Inspection

Offshore Oil & Gas Exploration

Oceanographic Sensor Deployment & Maintenance