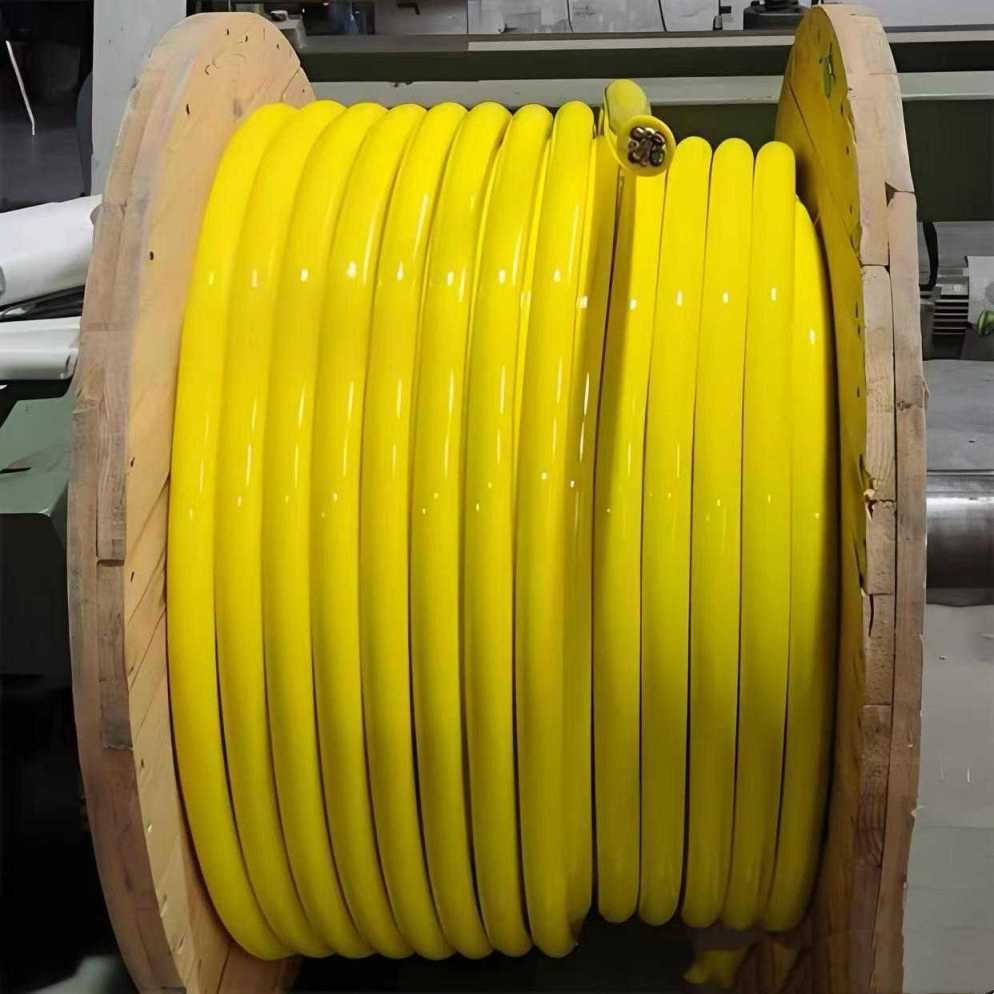

Subsea Hybrid Electro-Optical Cable

Custom Hybrid Electro-Optical Cables

Reliable Connectivity for Sensors, ROVs & Critical Subsea Assets

Our Subsea Hybrid Electro-Optical Cables are purpose-built to power and communicate with precision instruments, ROVs, and subsea sensors through a single, reliable cable. By combining robust electrical conductors with high-bandwidth fiber optics in a customizable design, we provide a streamlined, cost-effective backbone for scientific observatories, offshore monitoring, and deep-sea exploration, ensuring performance where it matters most.

Unified Design, Dual Mission

Our hybrid cable integrates two essential functions into one robust core:

Power Unit: Delivers medium/high-voltage electricity to energize offshore systems and subsea networks.

Fiber Optic Unit: Enables high-speed, low-latency data transmission for real-time monitoring, HD video, and scientific communication.

Engineered for Critical Performance

High Reliability: Built with multi-layer armor to endure extreme deep-sea conditions.

Exceptional Performance: Combines stable, low-loss fiber optics with efficient power conductors for reliable data and energy delivery.

System Simplification: One cable for both power and data streamlines installation and cuts lifecycle costs.

Flexible Customization: Tailored to your needs—from offshore wind farms to seabed observatories—in voltage, fiber count, armor, and length.

Robust Construction for Demanding Depths

Conductor

Material: Finely stranded and bunch-stranded, extra-fine oxygen-free copper wires / Anti-corrosion tinned copper wires. Customizable per requirement.

Cross-Section: Customized per customer specifications.

Structure: Anti-twist layered construction; grouped interstitial filling; pairs are first twisted, then layered and bundled.

Insulation

Material: Seawater-resistant compounded PVC / Corrosion-resistant Teflon (PTFE) plastic; specially formulated foamed thermoplastic elastomer / TPV / TPE. Customizable per requirement.

Color Coding:

For conductors ≤ 0.5 mm²: Color-coded (brown, black, blue, purple, pink, orange).

For conductors > 0.5 mm²: Black insulation with white numbering.

Cables with 3 or more cores include a yellow/green ground wire.

Water-Blocking Structure

Water-blocking compound filling.

Tensile Strength Member

Polyester yarn fiber / High-strength, tensile aramid fiber (e.g., Kevlar) / Optional finely stranded steel wires.

Inner Sheath

Modified low-viscosity, high-compression inner sheath. Optional based on environmental requirements.

Screening / Shield

Braided tinned copper screen with a density ≥ 85%.

Lay-Up Structure

Anti-twist layered construction; grouped interstitial filling; pairs are first twisted, then layered and bundled.

Outer Sheath (Jacket)

Material: Imported TPU compound or polyurethane (PUR) that is seawater-proof, water-resistant, acid/alkali-resistant, UV-resistant, and corrosion-resistant. Available in various colors, customizable.

Flexible Hybrid Electro-Optical Cable Solutions

Marine Renewable Energy: Connects and powers offshore wind, wave, and tidal energy systems.

Oil & Gas Production: Provides power and control for subsea infrastructure.

Scientific Networks: Supports seabed observatories with continuous power and data transmission.

Island Interconnection: Delivers both electricity and high-speed communication to remote islands.