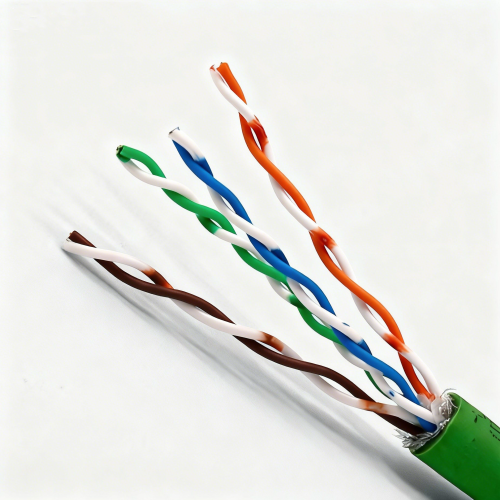

High-Flex Cable for Industrial Robots

Industrial Robot Cables: The Lifeline for Reliable Automation

Industrial robot cables serve as the critical "lifeline" of robotic systems, directly determining equipment reliability, service life, and maintenance costs. Our cables are engineered for harsh industrial environments, exceeding basic electrical connection needs to deliver superior mechanical performance, environmental resistance, and long-term dynamic service life. They provide stable and reliable transmission for power, signals, and control in your automated equipment.

Excellent Abrasion Resistance

Utilizes custom-engineered compound elastomer materials for the outer jacket, with a far superior abrasion resistance coefficient compared to standard PVC or ordinary PUR. This material offers both high mechanical strength and flexibility, effectively resisting constant friction and accidental impact against equipment, guides, or other cables. Dramatically extends replacement intervals in high-wear applications like drag chains and cable carriers, reducing downtime and lowering overall maintenance costs.

Outstanding High-Temperature Resistance

We offer various grades of high-temperature solutions. Standard dynamic applications can use high-performance PVC or PUR rated from -40°C to +90°C. For high-temperature areas like welding or foundries, we use PFA (Perfluoroalkoxy) or PTFE (Polytetrafluoroethylene) for insulation and jacketing, enabling a continuous service temperature of +200°C and a peak rating of +260°C.

Comprehensive Chemical Resistance

Our cable jackets are specially formulated to effectively resist common industrial chemicals like motor oil, hydraulic fluid, grease, coolant, diluted acids, alkalis, and saltwater. Ensures cable integrity in complex environments with chemical exposure (e.g., automotive manufacturing, chemical processing, food & beverage), preventing the cable from becoming the system's weak link.

Why Choose Our Cables?

Longer Service Life → Reduces replacement frequency and downtime.

Wide Environment Compatibility → From oily floors to high-heat zones.

Customizable Cycles → Tailored to your needs: 8M, 12M, 18M, 20M+ bends.

Engineered for Dynamics → Optimized for drag chains, cable carriers, and robotic 360° rotation.